Ventilation

Ventilation recommendations for 200-series sample roasters

Ensuring proper ventilation is important for roaster functionality and to create a healthy and safe working environment. A ventilation hose or 90 degree elbow must be attached before using the roaster.

Contents

Connecting the exhaust hose

Using the 90 degree elbow

Other ventilation options

Safety precautions and maintenance

Connecting the exhaust hose

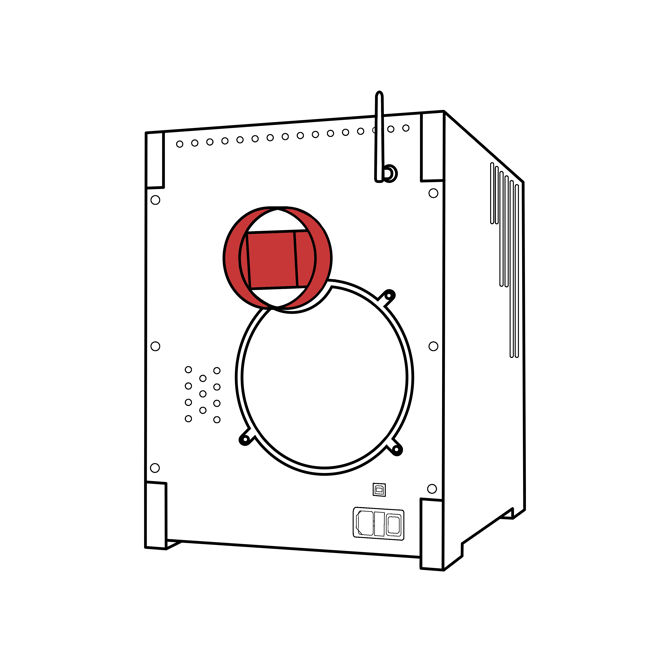

The roaster includes a 1.5 m exhaust hose as standard. If you need a longer hose, you can buy a 3 m hose on our webshop. To connect the exhaust hose to your roaster:

- Loosen the the hose clamp and slip it over the end of the hose.

- Stretch the end of the hose over the ventilation exit at the back of the roaster. It is a tight fit; you may find it helpful to twist the hose while pushing it onto the fitting.

- Tighten the clamp with a screwdriver

- Point the other end of the hose out of an open window or through a suitable hole to the outside.

- Alternatively, position the end of the hose underneath a suitable extraction system.

Using the 90 degree elbow

The elbow can be simply inserted into the ventilation exit and does not need a clamp. Direct the airflow away from the walls and towards a window or suitable extraction — you can position the elbow pointing sideways or upwards.

Other ventilation options

If you wish to conenct ROEST to your own ventilation system, it is recommended to use a flameproof metal hose with a diameter of 80 millimeters and keep ducting to no more than 3 meters long to ensure proper ventilation. Any ducting connected to the roaster should be maintained at neutral or slight negative pressure. Avoid connecting multiple roasters to a single duct, as airflow changes from one roaster will impact the functionality of the next.

Multiple machines in one duct, or longer ducts than 3 m are possible when using larger diameter ducting and active ventilation (i.e. an external fan) to maintain neutral / negative pressure in the duct. ![]() Any ducting connected to the roaster must be accessible for regular cleaning

Any ducting connected to the roaster must be accessible for regular cleaning

Additional requirements

Ensure at least 20 cm of space around the roaster to allow cool air to circulate. If the roaster or ventilation exit is positioned too close to the wall, the roaster may overheat. In this case, the heating element may shut down as a safety precaution.

The roaster must stand with all four legs on a hard surface to allow air to pass freely under the roaster.

The mesh on the rear of the roaster is an intake for cooling air, and there are additional ventilation holes on the side panels and back panel of the roaster. Ensure that these holes are not blocked in any way, and clean any dust off the rear mesh at the end of every roasting session.

Safety precautions

The roaster has powerful fans accessible for cleaning at the back. The impellers (fan blades) can cause injury to hands/fingers. Never place your hands or fingers inside the ventilation exit hole.

If a coffee bean or something similar gets sucked into the ventilation, it will be shot at high speed our of the ventilation exit hole. Therefore:

![]() Never look directly inside the ventilation exit hole when the roaster is ON.

Never look directly inside the ventilation exit hole when the roaster is ON.

![]() Never place the roaster with the ventilation exit hole facing people or animals.

Never place the roaster with the ventilation exit hole facing people or animals.

If you need to inspect the fans to check functionality while the roaster is running, wear suitable eye protection.

The roaster has multiple areas that get very hot. For safe operation, only use the handles, touch screen, and rotary knob to operate the machine. Touching hot surfaces may cause injury.

![]() Warning! These surfaces get hot during use:

Warning! These surfaces get hot during use:

|

Hot parts viewed from the front - drum, hopper, trier, and holes on both sides of the side panels. |

The ventilation exit in the back also gets hot. |

Be aware that other parts might get hot. Show caution.